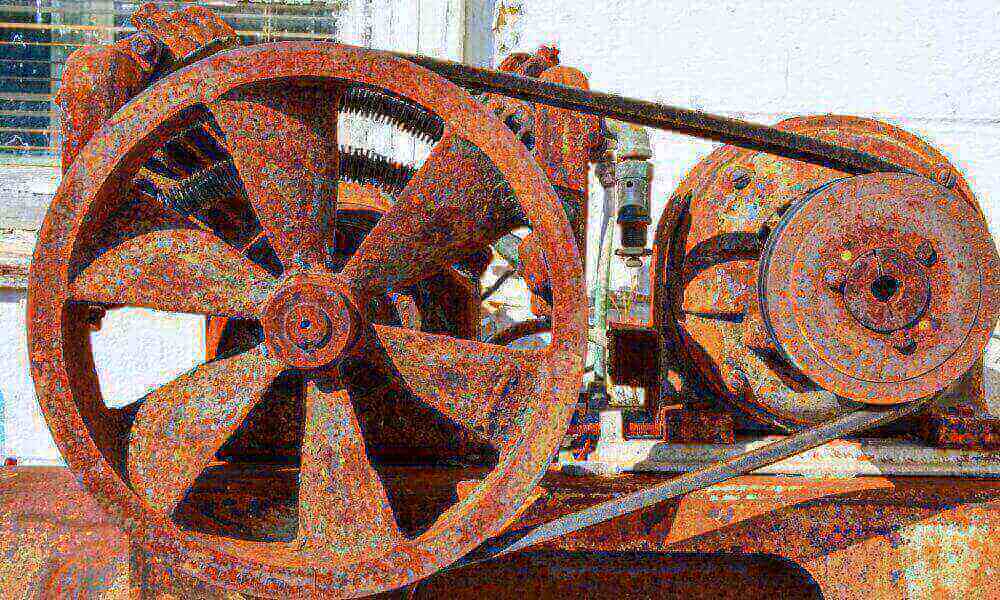

Rust is a common problem for machinery. It can happen to any machinery, and it can cause serious damage to your equipment. Rust is caused by oxidation, which means that iron reacts with oxygen in the air to produce iron oxide (rust). If you don’t take steps to prevent rust on your machines, they can become useless and break down.

Luckily, there are several ways you can prevent rust from forming on your machines. Some are simple, while others are more complicated, but all of them will help keep your equipment safe and working well for many years. They include:

1. Using Rust-Resistant Metals

One way to prevent rust is to use metals that don’t rust easily. For example, if you’re using a metal machine with a lot of water or humidity exposure, you should consider switching to stainless steel instead of regular steel. Stainless steel will not rust as quickly as other types of metal.

Other rust-resistant metals include aluminum, nickel-based alloys, titanium alloys, zirconium alloys, and other rare earth metals. These are the best options for preventing rust on your machinery because they are made without iron or steel—two elements that are highly susceptible to corrosion.

If you don’t have access to these materials, try electrostatic painting services in Miami or metal polishing services instead. These methods can produce a protective coating on your machinery that prevents it from rusting for years.

2. Electroplating

Electroplating is one of the most common methods to prevent machinery rust. This involves applying an aluminum layer to the surface of metal parts. It prevents them from being exposed to oxygen and other elements that would cause them to rust. You may also want to consider hiring residential and commercial painting services in Miami, FL, if you don’t have the time or resources necessary for this type of work yourself.

Electrostatic painting services in Miami will keep your machines looking good. The best way to do this is to choose a company with experience in industrial painting that can handle all types of equipment. They should also have high standards for safety and environmental responsibility, as well as provide excellent customer service from metal polishing services to the end.

For instance, in Miami, FL, Steeltech Electropainting is among the known companies that possess such qualities and will do the complete restoration services you may need. Or go for paint inspection services in Miami, FL to help you catch corrosion before it becomes a problem.

3. Store Your Tools and Equipment Indoors

That way, they’ll be protected from moisture and humidity—the main causes of rust. You might also consider looking for residential and commercial painting services in Miami, FL, which specialize in preventing rust on machinery. These professionals know how to treat machine surface, so it doesn’t rust quickly.

4. Use Anti-Corrosive Oils and Lubricants

Applying anti-corrosive oils and lubricants can be the easiest way to prevent rusting. These products contain additives that inhibit rust from forming, allowing you to preserve your machinery’s condition for longer.

Conclusion

If you’re looking for ways to prevent your machinery from rusting, then you’ve come to the right place. We’ve got all the information you need, from paint inspection services in Miami, FL to on-location electroplating services and equipment approved for rust-resistant.

We’re here to help you ensure your machinery stays in tip-top shape so it lasts as long as possible. Contact Steeltech Electropainting today.