Electrostatic Painting (ESP)

On site refinishing is exactly what it sounds like. Steeltech Electropainting, Inc.® will send a team of experienced craftsman to electrostatically apply high performance coating primers and finishes tailored to meet the needs of each individual substrates. Leaving a finish, which is either equal to or in most cases superior to a factory looking or performing finish.

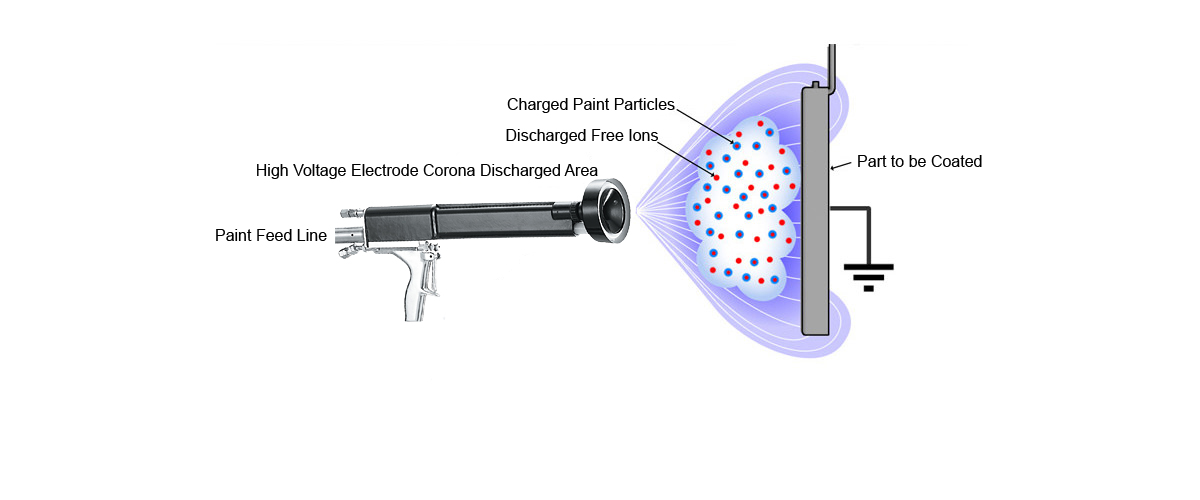

On a scheduled day a team of Steeltech® skilled craftsmen arrive with their mobile unit at the client’s workplace. The items to be refinished are first washed to remove dirt and grease, and then sanded to provide a tooth between the surface substrate and the new finish system. Masking is applied where necessary. The electrostatic coating process applies a mild negative electrical ground charge to the item to be refinished.

A special electrostatic spray gun charges the refinishing material with a positive electrical charge. The material is attracted like a magnet to the item. This assures uniform coating application with no fog, mist or overspray. Cleanliness is maintained at all times. A light tack coat is applied first, followed by a full wet coat, which dries within 30 minutes. Coatings are available in an array of decorator colors, including blends and special color.

Electrostatic is a term used for a special type of coating application equipment, which was developed back on March 6th, 1938, by a young man whose last name was Ransburg. He developed a system (primitive by today’s equipment) where an efficiently applied electric charge could be sent into liquid paint and then in turn ground the object they intended to coat, the particles of paint should be attracted to the surface of the object and there should be little waste. The demonstration of this technique was done using a metal salt shaker.

The shaker was hung in front of a small spray gun, and when the spray was turned on for a few seconds only one side was coated. Then four fine wires, spaced evenly around the shaker were charged with electrical current and the shaker was grounded. When the spray was repeated, it was coated on all sides, top, and bottom.

This is the same example that can be used today. A conventional spray paint application only goes to the surface directly in front of the spray gun. An electrostatic coating application wraps the material around the substrate ensuring an even mill thickness of the coating system. This leaves behind a finished coating without the unevenness, high and low spots of conventional paint spray applications. Brush painting of these types of substrates can not even be considered here due to their historically poor non scientific applications as well as being a non atomized applied finish.

Atomization is the breaking down of a liquid by air pressure into a small particle mass therefore creating a spray. This is how conventional paint spray equipment basically works. Air pressure is used to breakdown the paint and by doing so creates a radical forward velocity to blow paint onto the surface directly in front of the spray gun. As well as create a tremendous amount of damaging unsightly overspray

Modern Ransburg #2 process electrostatic equipment breaks down the coatings by an electrostatic charge and not by air pressure or any type of mechanical atomization.

The advantage this has over conventional spray painting is that there is minimal forward velocity, which keeps the particles of coating under the control of the electrical field. This positively charged coatings are in turn drawn onto the grounded substrate, wrapping the material around the object just as the salt shaker was coated due to positive vs. negative attraction and of course no overspray.

The Steeltech Electropainting, Inc.® electrostatic application system is the only way to refinish existing on site architectural aluminum and decorative metal back to a once again new product finish. All work is backed by written warranties against cracking, peeling, and delaminating, from exposure to Florida’s normal harsh environmental conditions.

Industries We Serve

On Location Electrostatic Painting (ESP) – Enhancing Surfaces with Precision and Efficiency

At Steeltech Electropainting, Inc.®, we specialize in providing top-notch on location electrostatic painting (ESP) services for a wide range of industries. With our state-of-the-art equipment and highly skilled team, we can revitalize your surfaces with precision and expertise. Our ESP technique ensures a flawless and durable finish that will enhance the appearance and longevity of your doors, windows, equipment, and more. Discover how our services can benefit your specific needs across various sectors.

Impact Doors & Windows

When it comes to impact doors and windows, durability and aesthetics are of paramount importance. Our on location electrostatic painting service for impact doors and windows offers a cost-effective solution to refresh and protect these vital components. Our highly trained technicians understand the unique requirements of impact doors and windows and employ advanced ESP techniques to ensure a smooth, even, and long-lasting finish. By choosing Steeltech Electropainting, Inc.®, you can enhance the curb appeal and durability of your impact doors and windows.

Residential & Condo Associations

Residential and condo associations require surfaces that can withstand daily wear and tear while maintaining an appealing aesthetic. Our on location electrostatic painting services cater to the specific needs of residential and condo associations, transforming surfaces such as fences, gates, railings, and more. With our ESP technique, we can breathe new life into these surfaces, providing a fresh and vibrant appearance. Trust Steeltech Electropainting, Inc.® to enhance the visual appeal and value of your residential and condo properties.

Grocery & Retail Facilities

In the competitive world of grocery and retail facilities, maintaining an inviting and professional appearance is crucial. Our on location electrostatic painting services for grocery and retail facilities can help you achieve just that. From shopping carts and shelving to storefronts and signage, our ESP technique delivers a flawless finish that rejuvenates these surfaces. By partnering with Steeltech Electropainting, Inc.®, you can create a welcoming and aesthetically pleasing environment for your customers, enhancing their shopping experience.

Machinery & Mechanical Equipment

Machinery and mechanical equipment are subject to constant use and exposure to harsh environments, leading to wear and tear over time. Our on location electrostatic painting services offer a cost-effective solution to refurbish and protect these vital assets. Whether it's manufacturing equipment, heavy machinery, or industrial components, our ESP technique ensures a durable and professional finish. Trust Steeltech Electropainting, Inc.® to help extend the lifespan and functionality of your machinery and mechanical equipment.

Office & Education Facilities

Office and education facilities require an environment that promotes productivity and professionalism. Our on location electrostatic painting services cater to the unique needs of these sectors, providing a fresh and modern look to surfaces such as cubicles, desks, lockers, and more. Our ESP technique allows for a quick turnaround time with minimal disruption to your operations. Partner with Steeltech Electropainting, Inc.® to create an inspiring and aesthetically pleasing environment for your employees and students.

Sport & Recreational Equipment

Sport and recreational equipment often endure extensive use and exposure to various weather conditions, leading to deterioration over time. Our on location electrostatic painting services offer a cost-effective solution to refurbish and protect your sports and recreational equipment. Whether it's playground structures, fitness machines, or sports equipment, our ESP technique ensures a vibrant and long-lasting finish. Enhance the safety and visual appeal of your sport and recreational facilities by choosing Steeltech Electropainting, Inc.®.

Pharmaceutical & Medical Equipment

In the pharmaceutical and medical industry, maintaining a sterile and clean environment is crucial. Our on location electrostatic painting services provide a seamless solution to refresh and protect your pharmaceutical and medical equipment. From lab cabinets and hospital beds to medical carts and storage units, our ESP technique delivers a hygienic and professional finish. Trust Steeltech Electropainting, Inc.® to help you maintain a pristine and visually appealing space that meets the stringent standards of the industry.

Contact Us Today

Transform your surfaces with our on location electrostatic painting services. Call our toll-free number at 1800-638-4413 to speak with one of our friendly representatives. Whether you need ESP for impact doors, residential properties, retail facilities, machinery, offices, sports equipment, or medical equipment, Steeltech Electropainting, Inc.® is your trusted partner for exceptional results. Enhance the durability, appearance, and value of your surfaces with our expertise and advanced ESP techniques. Contact us today to discuss your specific requirements and schedule a consultation.

Contact us for further answers to any questions or additional information you may require.

Our friendly and professional staff members stand ready to serve you!

Please note: For the convenience of our customers our operation hours are flexible to meet their needs and to reduce down time at their workplace.