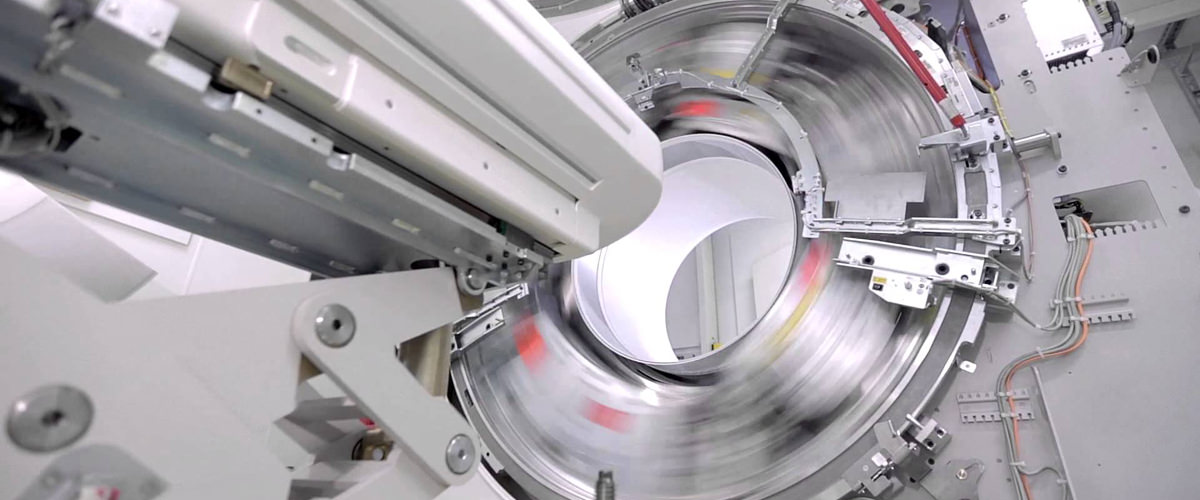

Electrostatic Painting (ESP)

Our experienced staff members work on site and provide superior quality electrostatic painting solutions tailored around your company’s unique needs, all without interrupting your operations.

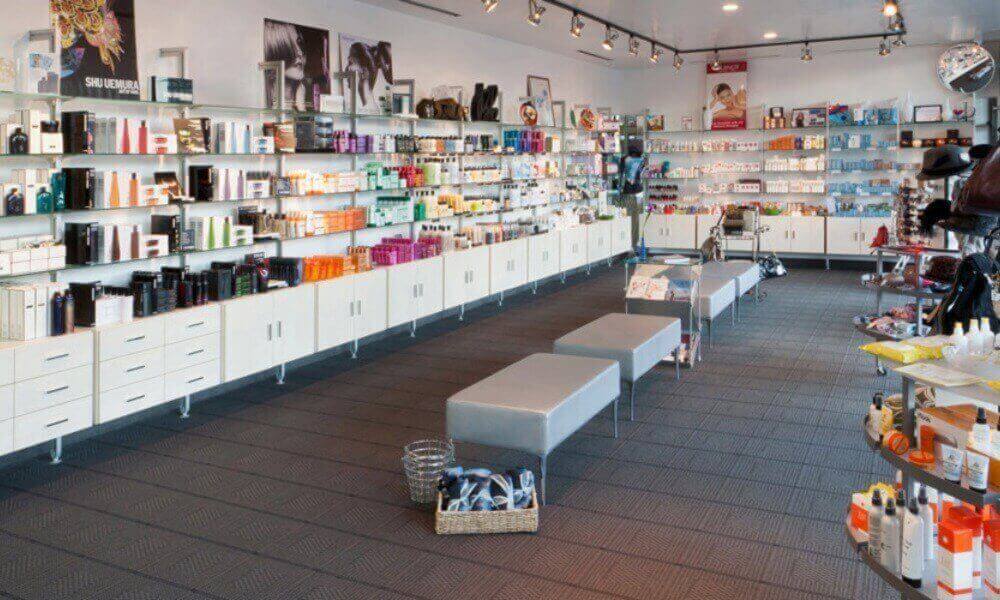

Restoration

Since 1974 our company has proudly served thousands of Florida’s businesses with unparalleled restoration and refinishing services in a cost effective and dependable manner.

Electrostatic Painting (ESP)

We specialize in bringing back old looking aluminun, art sculptures, stainless steel, copper, brass, nickel, chrome, and other hard coat polished finishes that show age, as a result of oxidation or neglect.